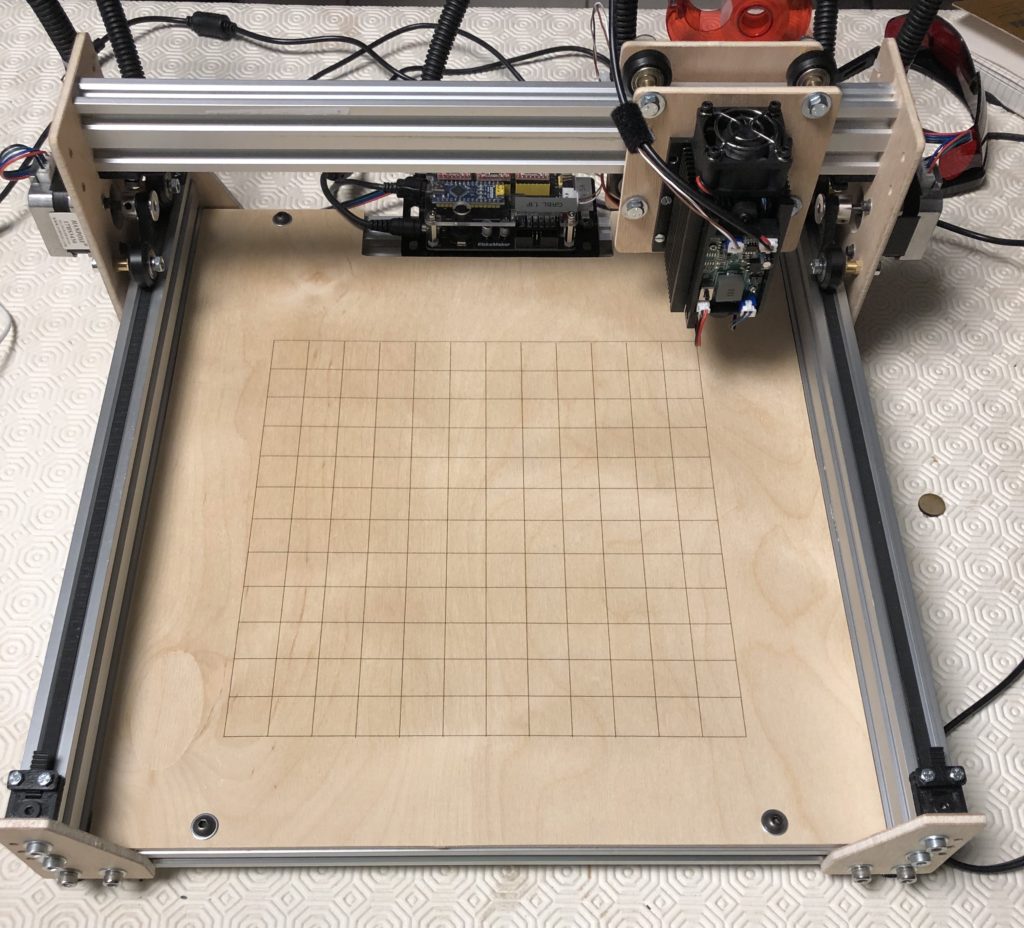

THE RESULT

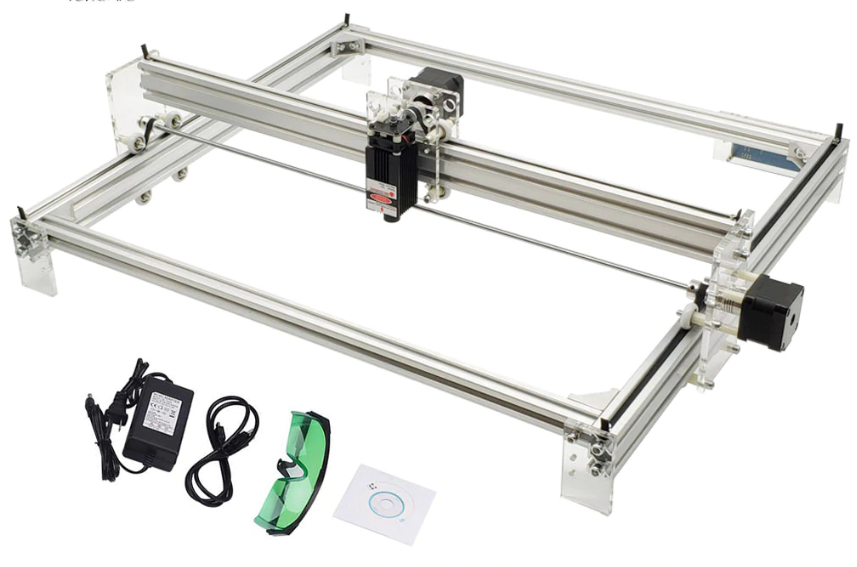

It is based on Eleksmaker Laser I saw on the internet. The construction seemed to me quite robust : I will explain later on the differents options for parts and assembly but the original is very fine.

Below, assembly instructions you can rely on :

https://wiki.eleksmaker.com/doku.php?id=elekslaser_a3_pro

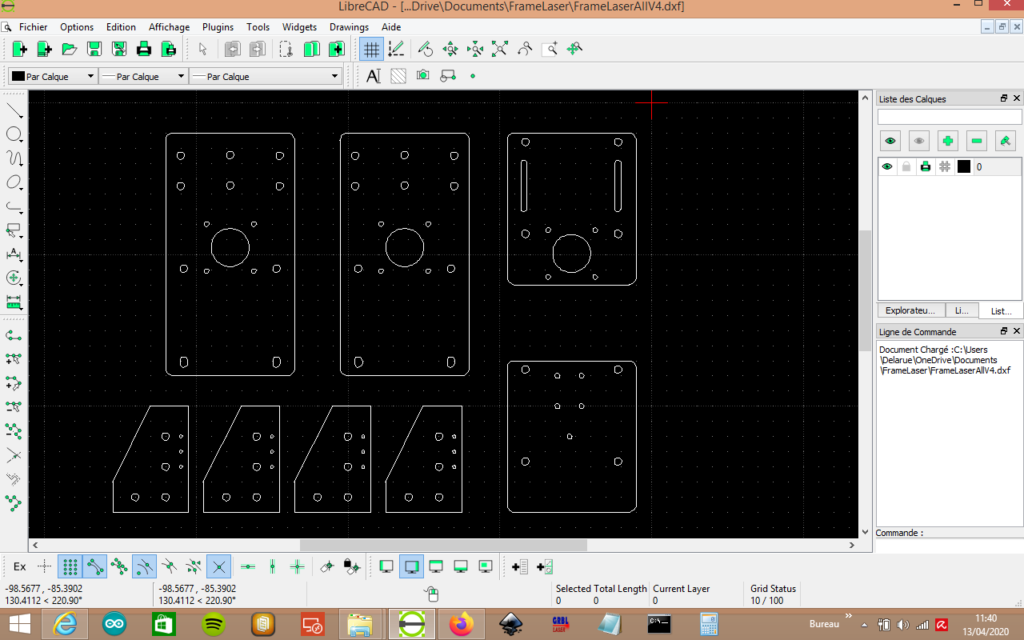

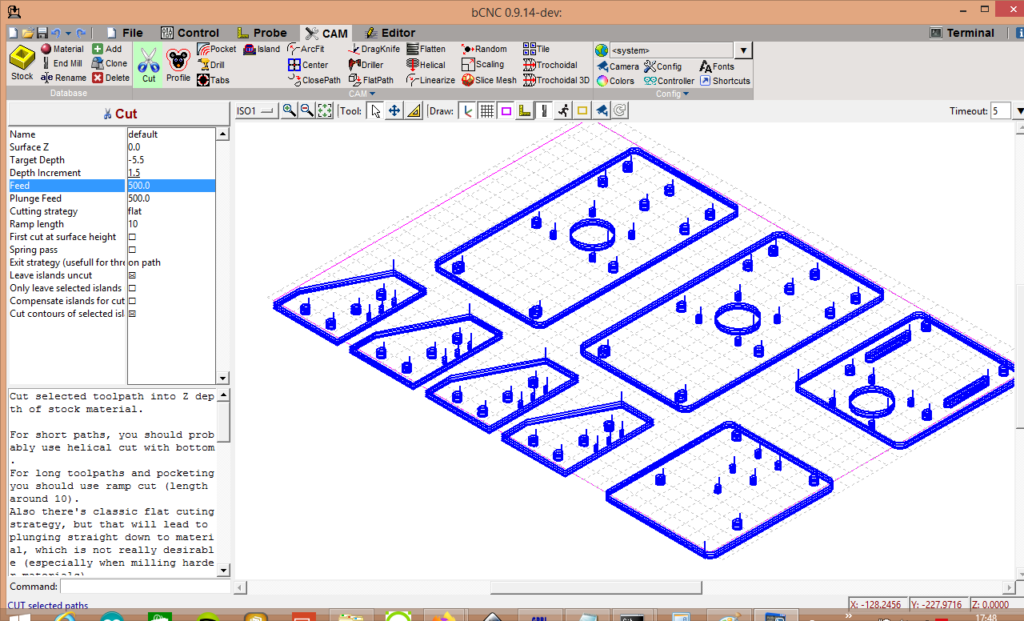

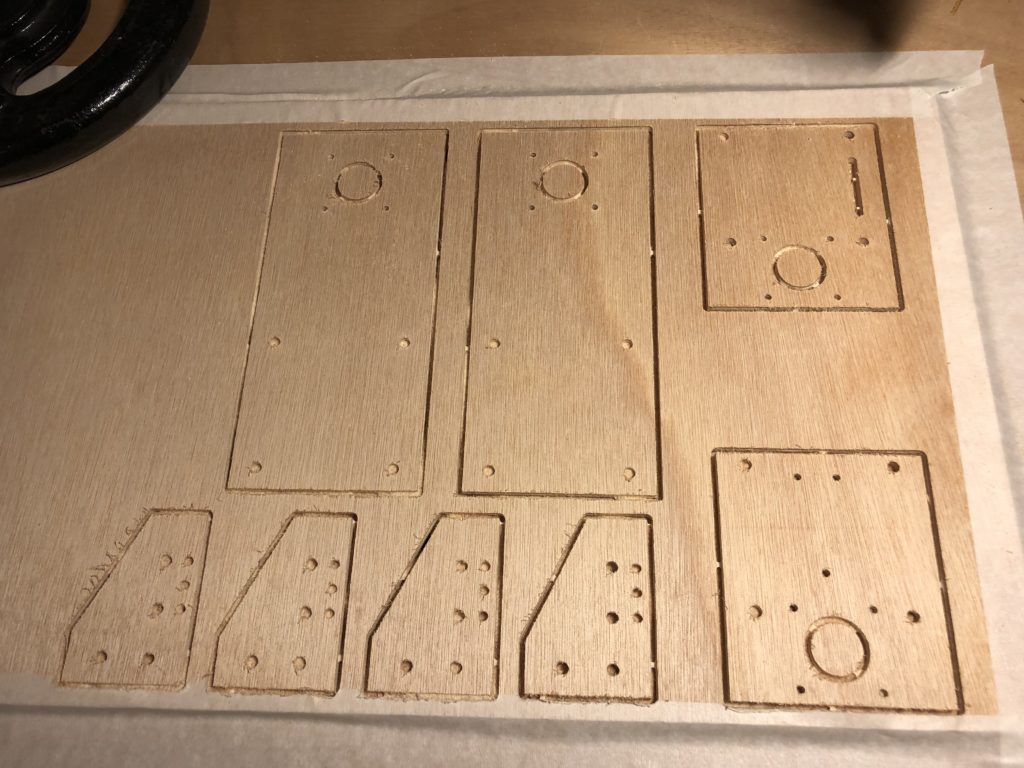

1 – PARTS & FRAME PARTS CREATION

I Use bCNC Software : big thanks to

Vasilis Vlachoudis and his great job!

I will detail its use later on

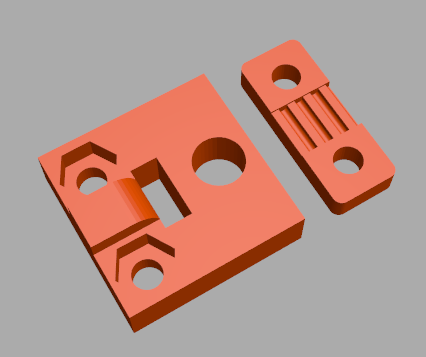

I also prepare 3D parts in STL format but it is far longer to print than CNC milling ; however in some situations, it can help

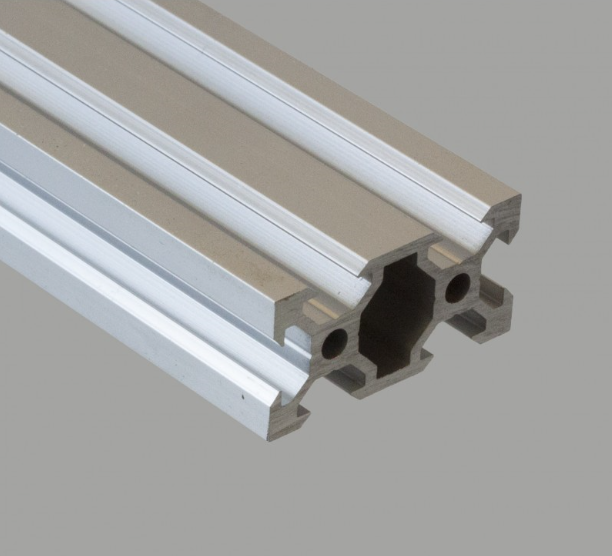

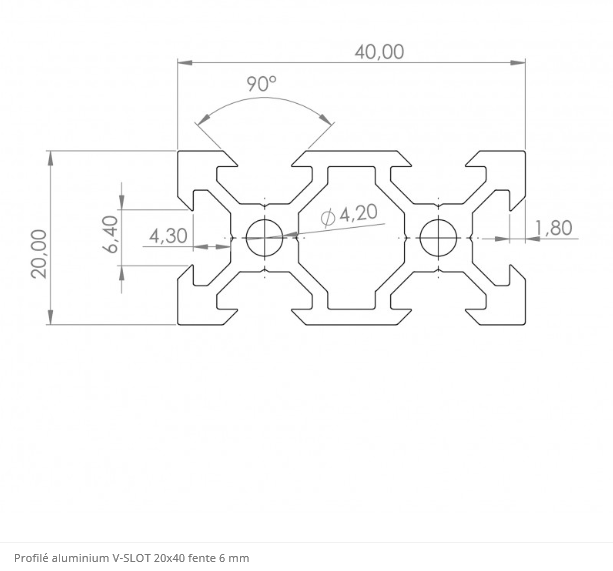

V-Slot 2040

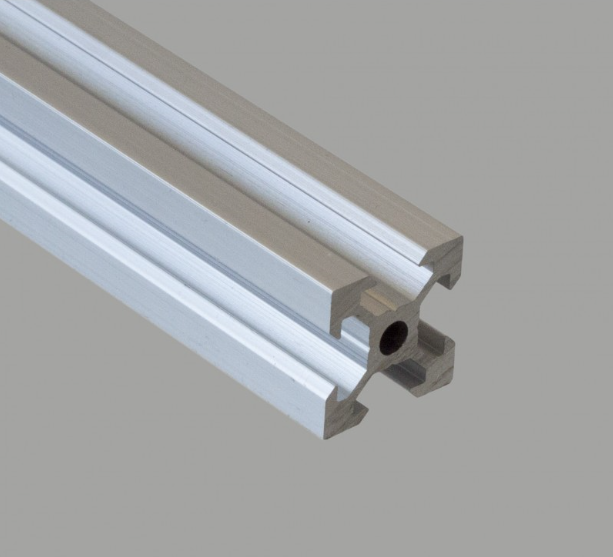

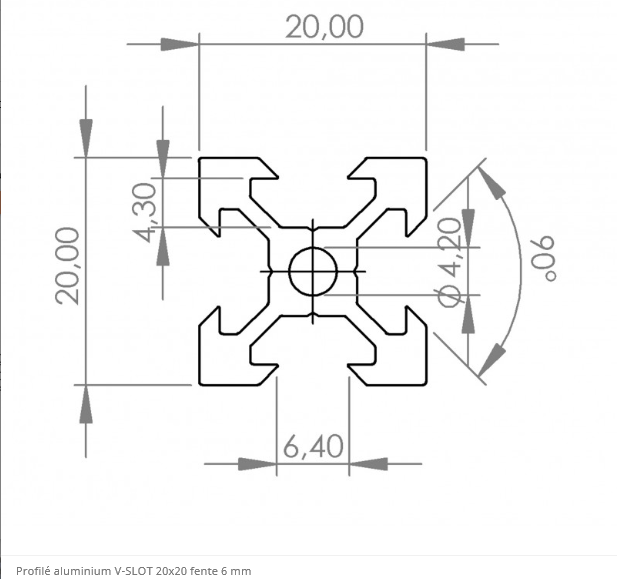

V-Slot 2020

V-Slot 20×20 X400 mm QTY: 2

400mm up To 1000 if you want bigger

V-Slot 20×40 X400mm QTY: 3

400 mm up To 1000 if you want bigger

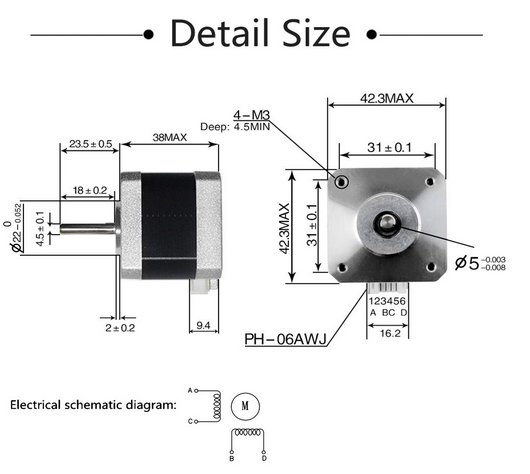

Nema 17 Motors 0.4A QTY : 3

I have 0.4A more powerfull 1.3 A for X axis could be goo too if you want to support a z-axis. Be carrefull power of three motors cannot exceed power of the card 3A with safety tolerance ..

If you cut the cable or wire it

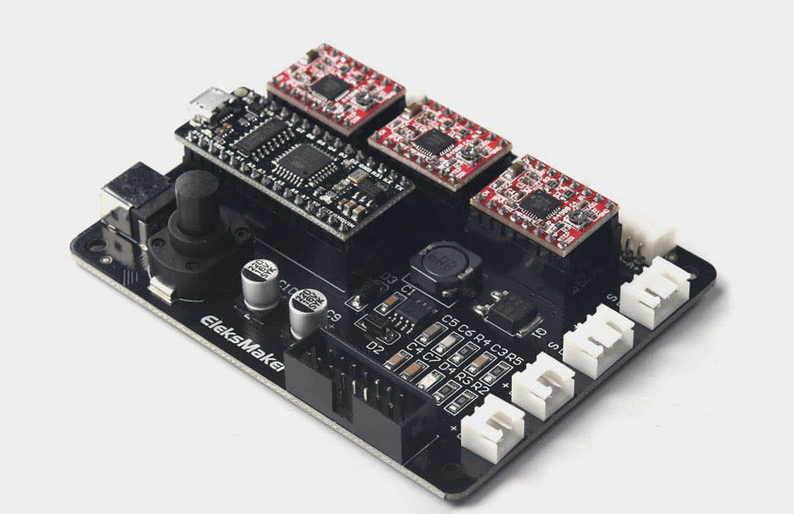

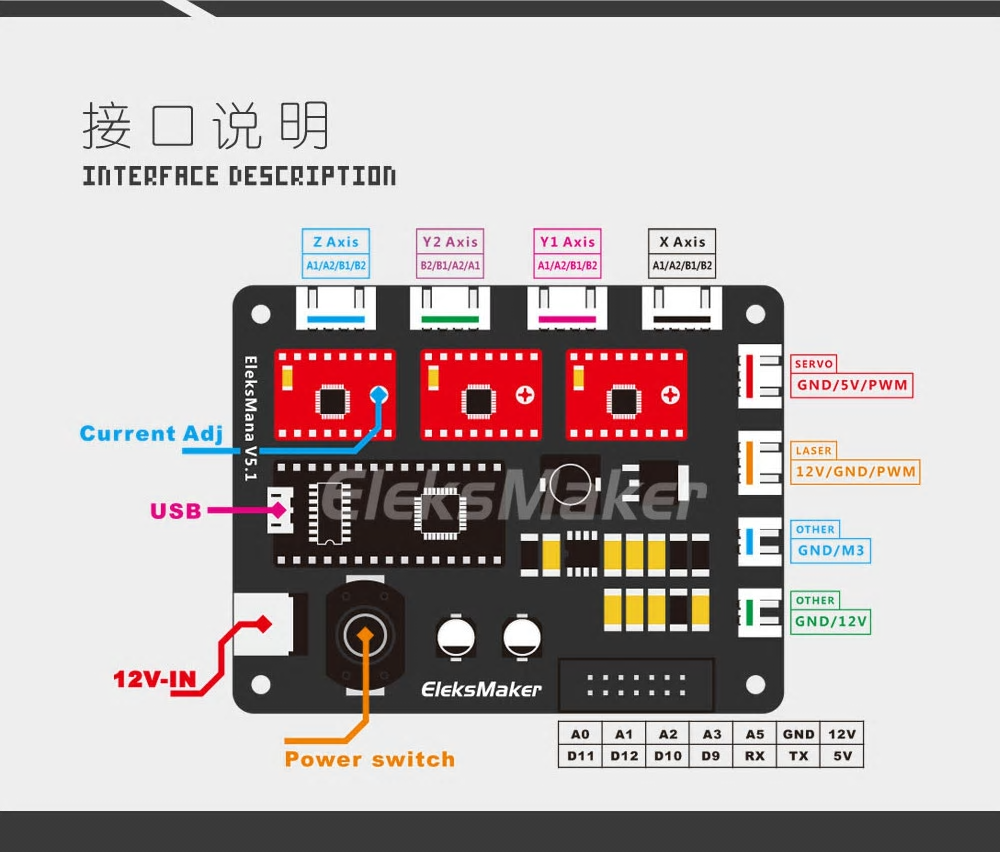

3 axis Mana Board Eleksmaker bought on Aliexpress QTY:1

I chose this board because It was possible to change Arduino Nano board and motors drivers : a good idea because I had to change Arduino Nano ATmega328P to upload GRBL 1.1.f .

The board was delivered with an Nano ATmega128 wich has not enough space.

I Chose 3 axis board in case of a Z-axis ; if you want only a 2 axis laser the board exist in 2 drivers version and is cheaper.

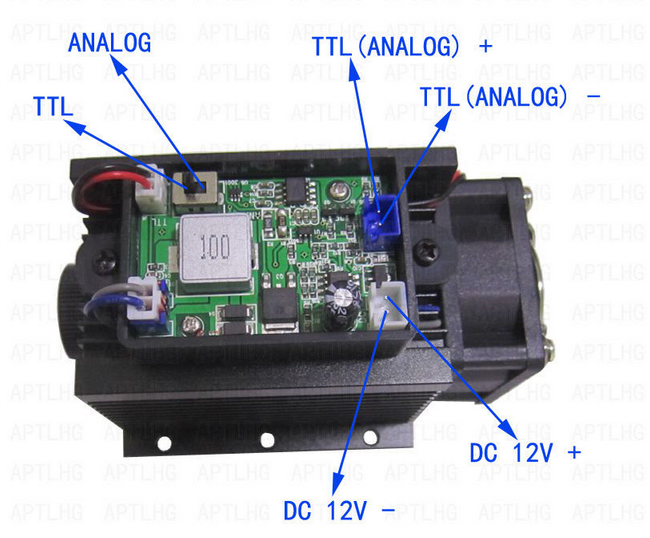

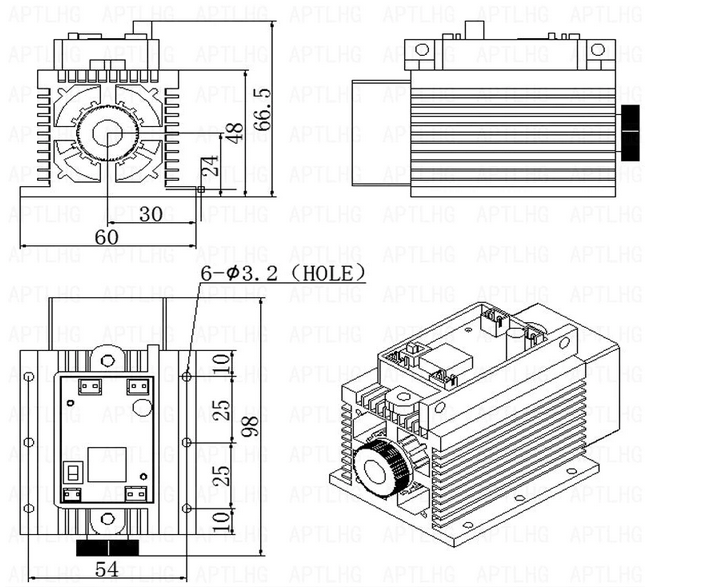

Chinese Laser 15W QTY:1

Or the power you want you will have to adapt mount holes I really have doubts about the power 🙁 . I would not encourage its use.

Wheels with 625ZZ bearing QTY :12

GT2 Gear 20 Teeth 5 mm Diameter QTY:3

GT2 Belt QTY:2m

Or more depending of the size of frame you want

Belt tensioner with M4x10mm Bolts an Screw QTY : 4

M4x10 mm for assembly

QTY : 8

Found on Thingiverse

End Stop QTY : 2

Eccentrics spacers QTY:12

Eccentrics really make the difference ; my first version was with standard spacer and everything was “floating”

M5 Bolts

M5x35 QTY : 8

M5x15mm QTY : 12

M5x8mm QTY : 12

M5x50 QTY : 4

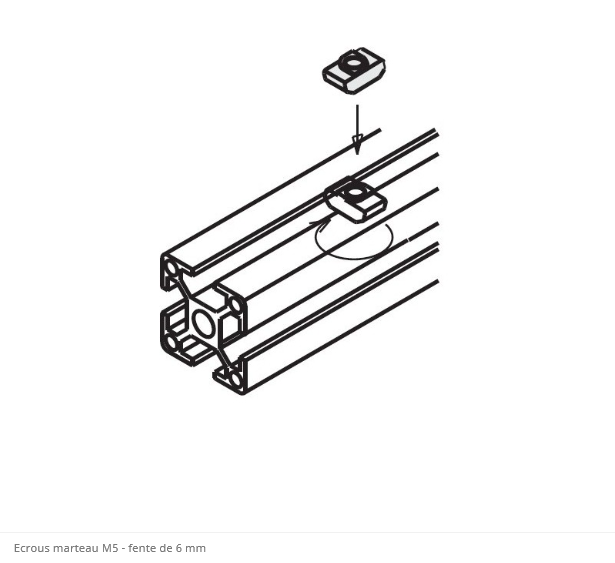

M5 Hammer Screw QTY : 30

Power Supply 220V ->12V 5A

XH 2.54 mm If needed for wiring cables

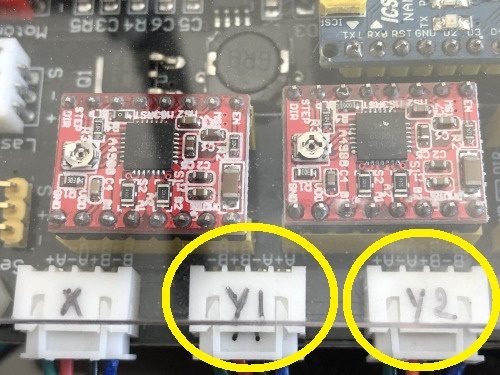

So that the Gantry on Y-Axis works fine the 2 motors need to work the opposit way ! They are looking at each other .. So you will probaly have to revert one of your cable. As written on the board Note : A+A-B+B- for Y1 and Y2 motors. For reverting your JST connector you need the tool below :

For connectors below … not easy to use the first time

Tutorial

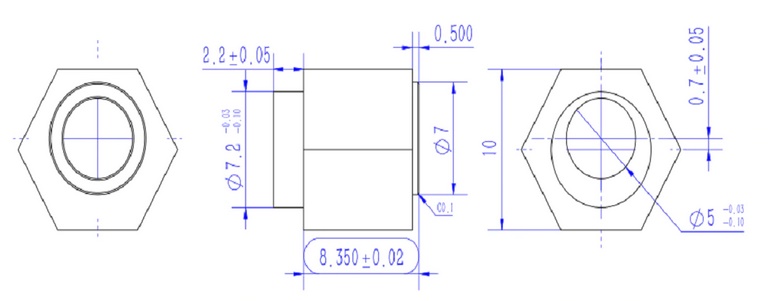

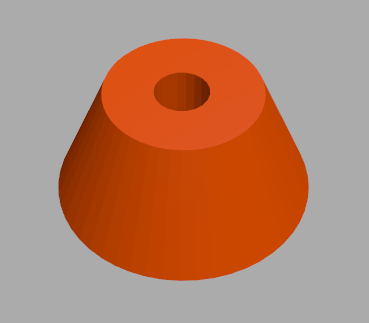

Feet for the laser I designed QTY : 4

Inside diameter 10mm QTY : 2m

Or more if you extend size of laser

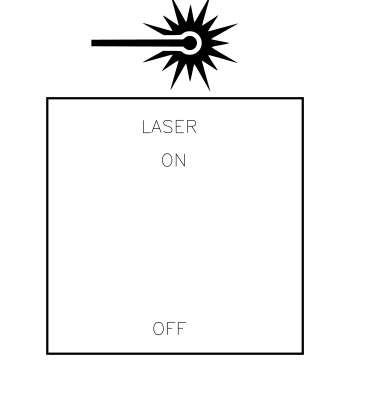

Laser Switch optional but usefull

Small svg file to get you switch nicer

2-CONFIGURATION OF GRBL BOARD

Then configure GRBL 1.1 f Configuration according to : https://github.com/gnea/grbl/wiki/Grbl-v1.1-Configuration Buy the way : thanks a lot to GRBL Team, they realise a great job !

Grbl 1.1f [‘$’ for help]

[MSG:’$H’|’$X’ to unlock]

$0=10 (Step pulse time)

$1=25 (Step idle delay)

$2=0 (Step pulse invert)

$3=3 (Step direction invert)

$4=0 (Invert step enable pin)

$5=0 (Invert limit pins)

$6=0 (Invert probe pin)

$10=3 (Status report options)

$11=0.050 (Junction deviation)

$12=0.002 (Arc tolerance)

$13=0 (Report in inches)

$20=1 (Soft limits enable)

$21=0 (Hard limits enable)

$22=1 (Homing cycle enable)

$23=3 (Homing direction invert)

$24=25.000 (Homing locate feed rate)

$25=500.000 (Homing search seek rate)

$26=25 (Homing switch debounce delay)

$27=3.000 (Homing switch pull-off distance)

$30=1000 (Maximum spindle speed)

$31=0 (Minimum spindle speed)

$32=1 (Laser-mode enable)

$100=80.000 (X-axis travel resolution)

$101=80.000 (Y-axis travel resolution)

$102=400.000 (Z-axis travel resolution)

$110=1000.000 (X-axis maximum rate)

$111=1000.000 (Y-axis maximum rate)

$112=1000.000 (Z-axis maximum rate)

$120=100.000 (X-axis acceleration)

$121=100.000 (Y-axis acceleration)

$122=200.000 (Z-axis acceleration)

$130=240.000 (X-axis maximum travel)

$131=240.000 (Y-axis maximum travel)

$132=10.000 (Z-axis maximum travel)

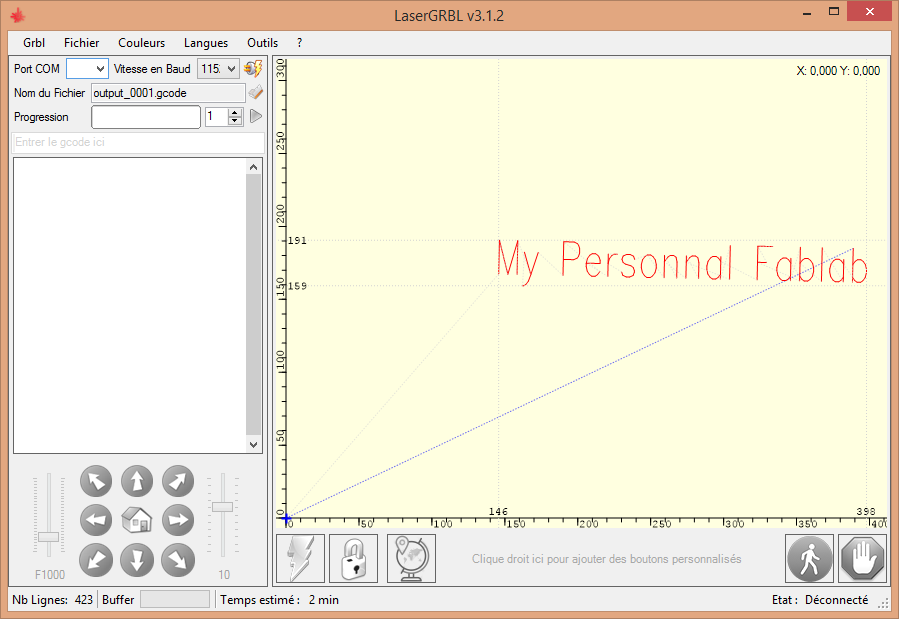

4 – ENGRAVING WITH LaserGRBL

// I use this G-CODE to put laser in low power mode for focusing it

G1 F100

M03 S1

M03 S0

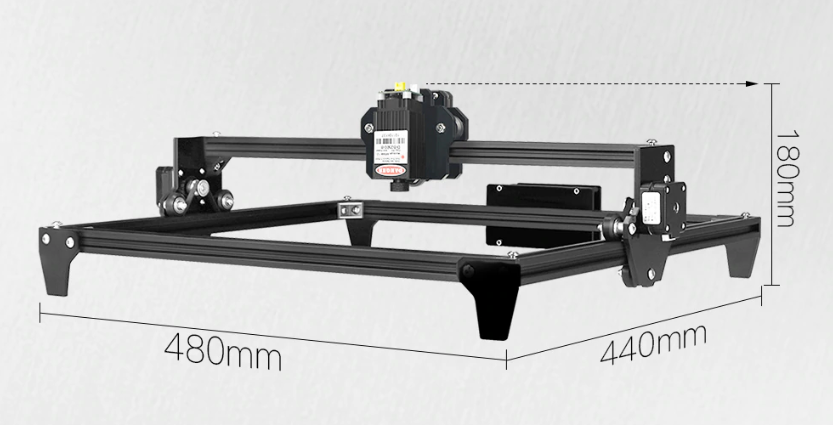

5 – OTHER POSSIBLE FRAMES …

Only one motor for Y Axis the second one has been replace with a rod . Don’t know about accuracy

X-Gantry profile 4020 has been replaced with a 2020 profile and 2 corners. Y-axis sliders are also in 2020 profiles : Less expensive

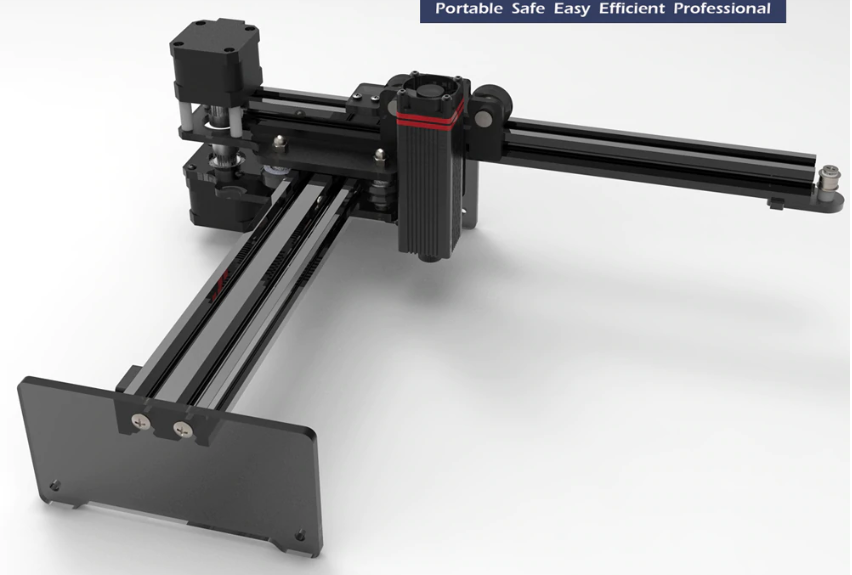

A minimalist one for small engraving/cut